Custom Chevron Conveyor Belt

Chevron conveyor belts are highly effective for transporting sand, coal powder, grain or other powder or granular materials or materials packed in bags or boxes on incline though they can transport coal or mineral ore just like ordinary conveyor belts. They can transport powder or granular materials on 17°~28° inclines and materials packed in bags or boxes on 30°~35°inclines.

Types Of Chevron Conveyor Belt

Chevron conveyor belt is composed of belt carcass and pattern. Chevron shape and height (depth) may be different because of different conveyor material and gradient of conveyor.we can supply diamond, chevron, fishbone, herringbone, V and Y patterned conveyor rubber belt for our customers.

Type v15 OPEN

Type V15 Closed

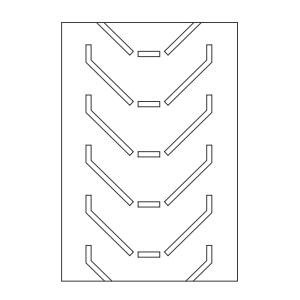

Type C32

Type V3,V5,V6,V10

type multi V6

tYPE C25

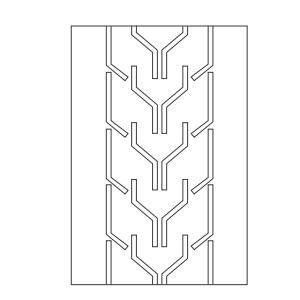

Type Y17

Type Y17

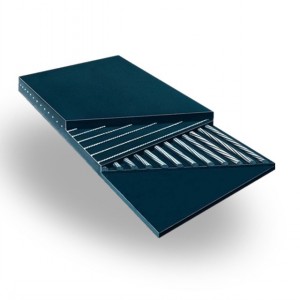

Hot Selling Chevron Type details

For gradient angles of more than 18°, bulk material cannot be trans ported using ordinary textile conveyor belts. Chevron conveyor belts are used instead.

As there are many different application areas, flow rates and operational specifications Huadu® provides an abundant portfolio of open and closed profile types. For individual client requests regarding the height or type of profile, tailor-made solutions can be realized.

Type V3, V5, V6, v10

- height of chevron (mm): 3mm, 5mm, 6mm, 10mm

- width of chevron (mm): 600-1400mm

- dist. betw. chev. (mm): 76mm, 80mm, 100mm,150mm

- width of belt (mm): 500-1400mm

Type C25

- height of chevron (mm): 25mm

- width of chevron (mm):450mm, 550mm, 750mm

- dist. betw. chev. (mm): 330mm

- width of belt (mm):500-1200

Type Y17

- height of chevron (mm): 17mm

- width of chevron (mm): 440-950mm

- dist. betw. chev. (mm): 330mm

- width of belt (mm): 500-1400mm

Wanna customized conveyor belt ?

Do you meet those problemt when you ordered chevron conveyor belt

- The joints on the conveyor belts are not properly aligned or connected, causing them to come apart or become damaged during use.

- The rubber pattern on the conveyor belts is not properly pressed or formed, causing it to wear down or become damaged more quickly than expected

how we solve those problem

- Our workers have more than 20 years on conveyor belt joint, then we can ensure we can joints are properly aligned and connected.

- For the pattern issue,we will adjust our machine manufacturing process to ensure that the pattern is being properly pressed and formed.use higher-quality rubber materials to ensure that the pattern is more durable.

The Knowledge About rubber conveyor belt

5 Key Factors To Consider When Choosing A Rubber Conveyor Belt

5 Tips to Choosing a Good Rubber Conveyor Belt Table of contents 添加标头以开始生成目录 If you’re in the market for a rubber conveyor belt, you’ll want to make sure you choose the right one for your needs.

A Brief Self-Nomination, Why Choose Huadua?

- Over 20 years of rubber conveyor belt manufacturing experience

- All rubber conveyor belt Meet and exceed ISO:9001 standards

- Complying criteria as DIN-22102 , AS-132, RMA,SANS-1173,BS-490

standards. - Flame resistant conveyor belt tested and certified with SGS

- One-Year Quality Guarantee, reply in 2 hours.

The FAQs About Rubber Conveyor Belt

Please note that the final cost depends on the customized service you require, the specifications of the raw materials used, the relevant national laws, and the distance of transportation. Take the example of booking a tall container of products:

Belt improperly spliced or wrong fasteners?

Use correct fasteners. Retighten (as recommended by manufacturer) after running for a short while. If improperly spliced, remove belt splice and re-splice

Pulleys too small

Use larger-diameter pulleys as specified.

excessive tension

Recalculate and adjust tension

Pulley lagging worn

Replace worn pulley lagging. Use grooved lagging for wet conditions. Repair or replace protruding loose bolts.

Material falling between belt and pulley

Use skitboards properly. Remove accumulation.

Insufficient belt strength

If centers or loading are increased, or speed reduced recalculate tensions and fit the correct huadu belt.

Pretension too high

Recalculate and adjust counterweight accordingly. If screw take-up, reduce take-up tension to point of slip, retighten slightly. vestibulum mollis diam.

Differential speed wrong on dual pulleys or drives

Make necessary adjustment. Observe operation closely.