Sidewall Conveyor Belt

Sidewall belts are suitable for horizontal to vertical transport (up to 90°) of bulk material.

This can reduce the number of transfer points during operation and has a positive outcome in terms of producing in an energy and capital saving mode of operation.

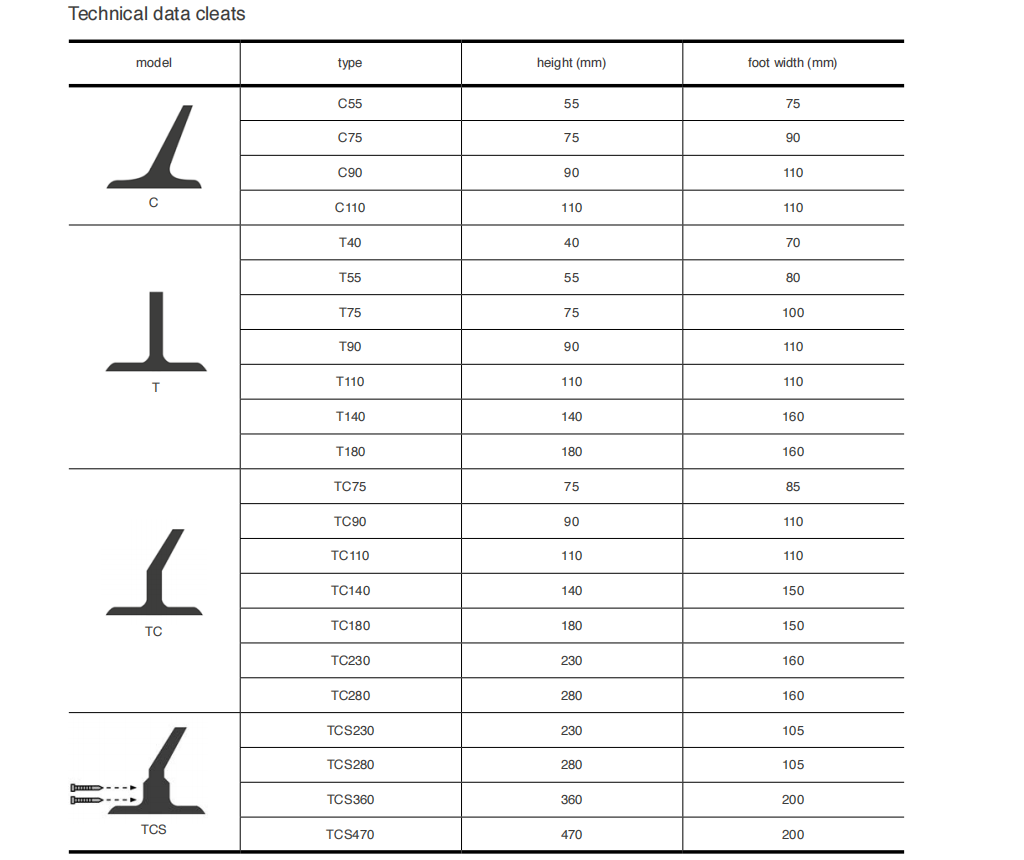

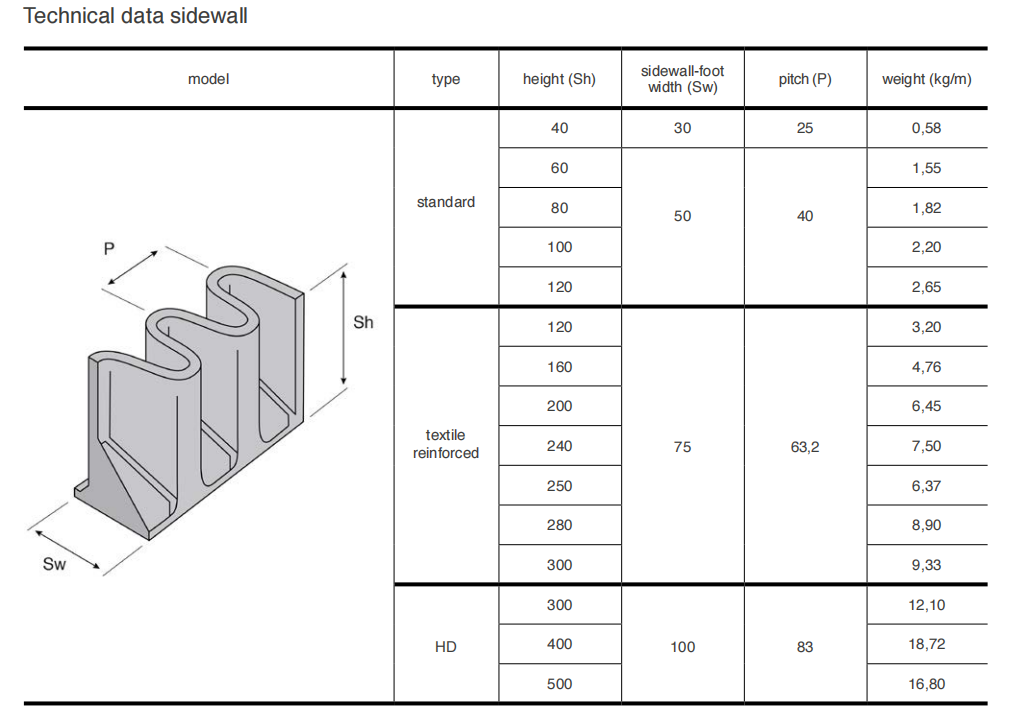

Huadu offers its customers a large portfolio of possible combinations of cleats and sidewalls in different height up to 500 mm.

Description of sidewall conveyor belt

Looking for a conveyor belt that can handle steep angles and high capacity while taking up minimal space? Look no further than Huadu’s sidewall conveyor belts!

Our belts are available in a variety of rubber qualities, including abrasion-resistant, heat-resistant, fire-resistant, cold-resistant, and oil-resistant options. The reinforcement inside the sidewall provides a perfect combination of flexibility and strength, effectively preventing tearing.

Our special rubber compounds also provide superior resistance to impact, rip, and tear, ensuring that our cleats can withstand even the toughest conditions. And with twice-hot vulcanizing, our belts offer outstanding flexibility, strength, and durability.

Overall, Huadu’s sidewall conveyor belts are highly durable, with low elongation and long-lasting performance. So whether you’re working in mining, construction, or any other industry that requires reliable conveyor belts, choose Huadu conveyor belt for the best in quality and performance.

Sidewall Conveyor Belt

- hot vulcanisation of cleats and sidewalls on the base belt

- maximum width of belt 2000 mm

- maximum cleat and sidewall height 500 mm

- delivered as endless belt or open length

lt is designed by most experienced engineers to corrugate shape and can withstand highly stress and repeated flexing.

Cleats are the main part to carry materials in a high capacity and steepangle,which is T or TC type usually.

These two parts are connected with base belt by second hot vulcanizing,which creat a super-strength bond between sidewall,cleatsand base belt.

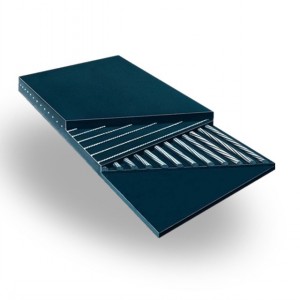

Sidewall Conveyor Belt Without Cleats

- Belt Core material: CC56; NN; EP; ST

- Width:300-2400mm

- Ply:2-10

- Core rubber: top cover: 1.5-10mm bottom cover:1.5-10mm

- EP conveyor belts have better impact resistance compared to CC56 and nylon rubber conveyor belts.

Download the catalogue

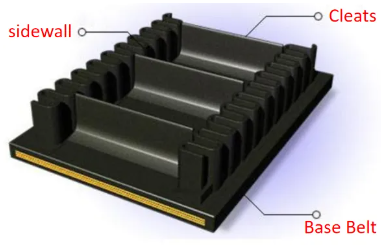

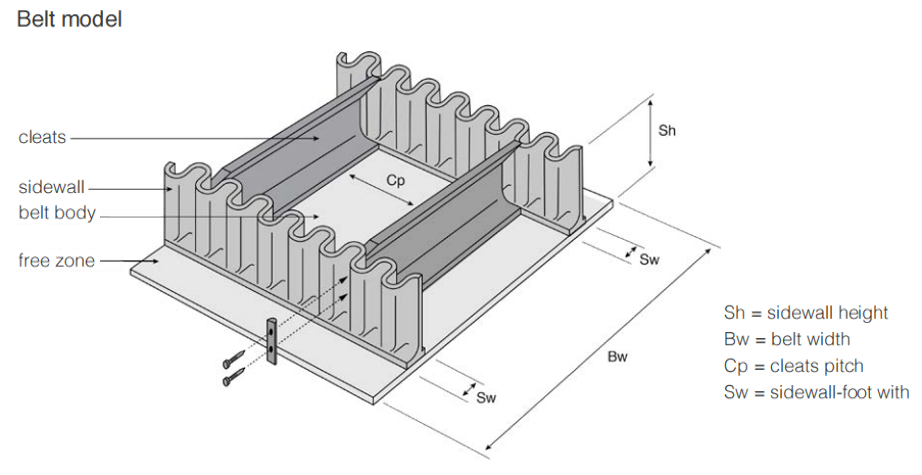

Sidewall conveyor beltsstructure

Sidewall conveyor belts are composed of three parts:base belt,sidewaland cleats.Sidewall effectively protect bulk materials from sideslip andscatter.

lt is designed by most experienced engineers to corrugate shape andcan withstand highly stress and repeated fexing

Cleats are the main part to carry materials in a high capacity and steepangle,which is T or TC type usually.

These two parts are connected with base belt by second hot

vulcanizing,which creat a super-strength bond between sidewall,cleats

and base belt.

Take a look at our Conveyor belt factory

Because sidewall belts are always custom-made products, please contact the Huadu service team for receiving an individual offer that meets your requirements.

Conveyor belt package and shipping

Huadu will provide packaging advice based on the type of conveyorbelt you ordered.our conveyor belt provides three packagingmethods: round roll,glasses roll & oval roll.Conveyor belt outsourcing pp tarpaulin, color can be customized, andalso provide pallet (wood/metal) and iron frame options.

We usual shiped the order out within 15-20 days!

All You Need To Know About Fabric conveyor belt

Fabric conveyor belts are widely used in various industries for the transportation of materials. These conveyor belts are made of different materials, such as cotton, nylon, and polyester, which are coated with rubber to provide grip and traction.

The advantages of fabric conveyor belts include their high tensile strength, good abrasion resistance, and flexibility. They are also cost-effective and can be customized to meet the specific needs of different industries.

To ensure the longevity and effectiveness of fabric conveyor belts, proper maintenance is crucial. This includes regular cleaning, inspection, and lubrication of the conveyor system. It is also important to choose the right type of fabric conveyor belt for the specific application, taking into account factors such as load capacity, speed, and environmental conditions.

Customer feedback video

What Are Sidewall conveyor belt Used For?

(1) Mining

(2) Iron and steel industry

(3) Foundries

(4) Port and handling

(5) Coal and biomass power plants

(6) Recycling industry

(7) Sand and gravel industry

(8) Stone quarries

A Brief Self-Nomination, Why Choose Huadu

- Over 20 years of rubber conveyor belt manufacturing experience

- All rubber conveyor belt Meet and exceed ISO:9001 standards

- Complying criteria as DIN-22102 , AS-132, RMA,SANS-1173,BS-490

standards. - Flame resistant conveyor belt tested and certified with SGS

- One-Year Quality Guarantee, reply in 2 hours.

The FAQs About rubber conveyor belt

1) Can I get one sample to test?

Yes, No problem free samples, just need you bear the shipping cost.

The sample cost can be refundable after order confirmation.

2) What is the delivery time after payment?

1. 3-5 days for sample

2. 15-20 days for mass production. If urgent,we have green channel, can do within 10 days

3) Can I custom my logo and appoint the color on the product?

Yes,just offer me your logo design with format so that our designer will make adisplay for your reference

4) How about package?

1. Inner is packed on round rubber core with 30cm diameter and 12cmx12cmsquare hole

2. Outer is packed with one ply water-proof Pp fabric

5) Can you support customized

Yes, we can support customized conveyor belt width, thickness, length

6) waht's the MOQ

Support low MOQ, like 10 meter per roll