Steel Cord conveyor belt

A steel cord conveyor belt is a type of conveyor belt that uses steel cords as the reinforcement material. The steel cords are embedded in a rubber conveyor belt, which provides both strength and flexibility. This type of conveyor belt is commonly used in heavy-duty applications, such as mining and construction, due to its high tensile strength and ability to transport heavy materials over long distances. The steel cord conveyor belt is also known for its durability and resistance to abrasion, making it a reliable choice for industries that require continuous and efficient material handling.

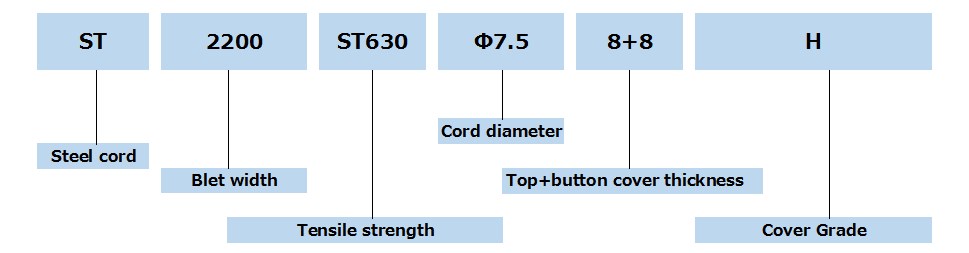

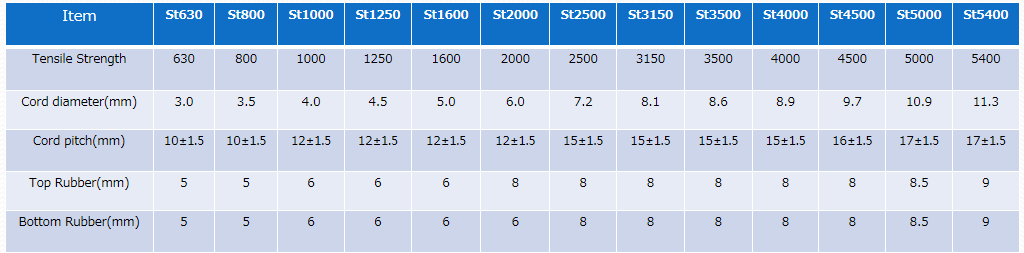

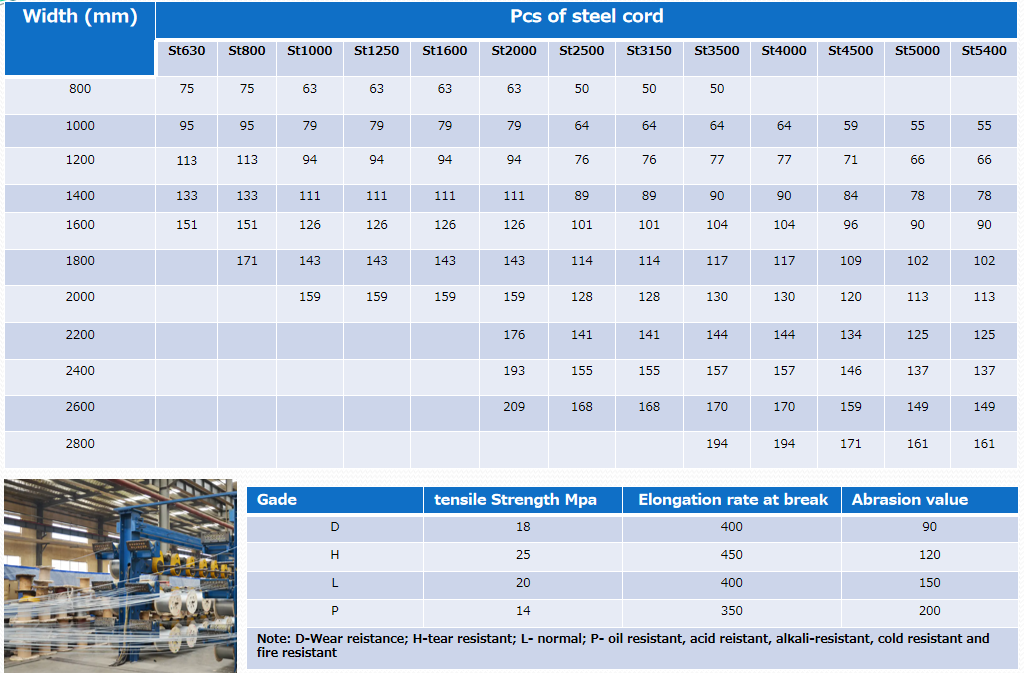

Description Of Steel Cord Conveyor Belt

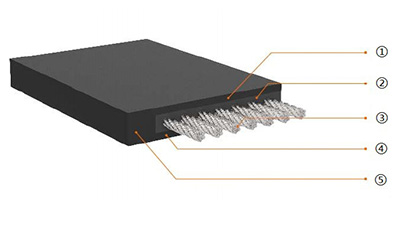

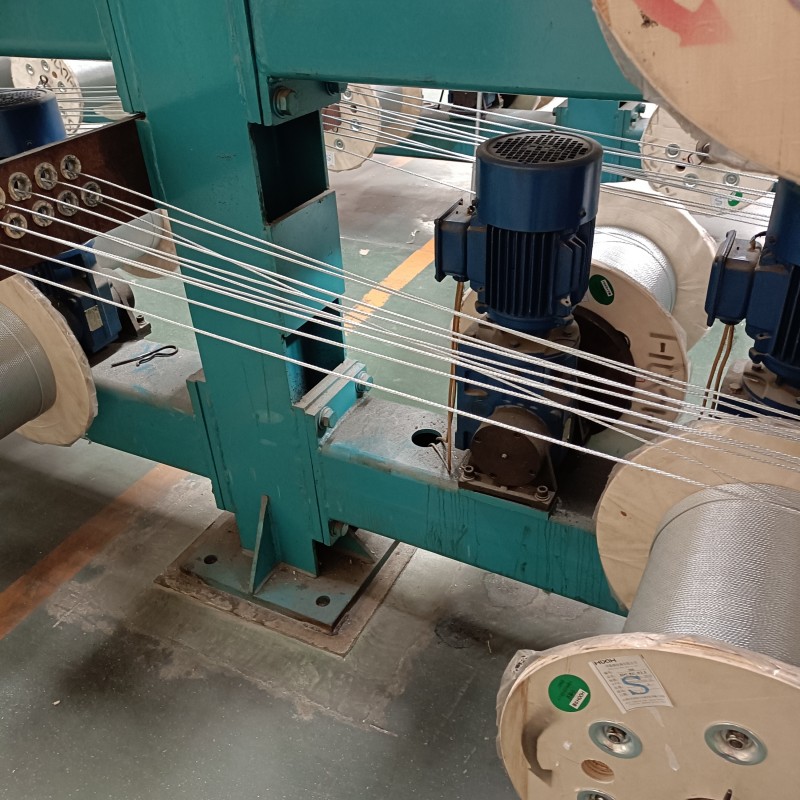

The steel cord conveyor belt consists of a multi-layer steel cord core and rubber covering,the production process includes steps such as steel cord weaving, rubber mixing, extrusion and vulcanization,

Normal Steel cord conveyor belt

- ① Upper /Top cover layer

- ② Core rubber

- ③ Steel wire

- ④ Bottom cover layer

- ⑤ Side rubber

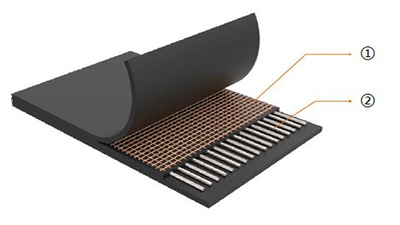

Tear Resistant steel cord conveyor belt

- ① Anti-tear steel cord

- ② Steel wire

Based on the traditional version, we added steel cords and fiber cords perpendicular to the steel wire

- prevents length-wise tearing by foreign substances or sharp objects

- prevents broken steel cord from protruding through coverrubber

- provides high withdrawal strength (in stationarytests)

- reduces risks for belt breakage by impact

Cord Structure

- 7×7 :Applied to low tension lines

- 7×19 :Applied to high tension lines

Download The Catalogue

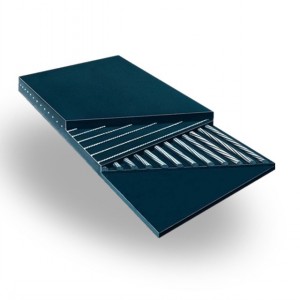

Steel Conveyor Belt Structure

top 5 benefits of choosing steel cord conveyor belts.

Top 1: Strong Durability

Steel cord conveyor belts are extremely durable, making them the ideal choice for high-traffic areas and continuous heavy-duty operations. The steel wire ropes used in the construction of these belts provide a high level of tensile strength and wear resistance, ensuring that the belt will maintain its integrity for longer periods of time.

TOP 2: High Load Capacity

Thanks to their strong and sturdy construction, steel wire rope conveyor belts are capable of handling large and heavy loads with ease. Their ability to support high weights makes them ideal for applications such as mining, construction, and industrial processing.

Top 3: Safety and Reliability

Steel cord conveyor belts offer a high level of safety and reliability due to their smooth surface and durability. They are less likely to experience tears or rips, which reduces the potential for accidents and equipment failure. Additionally, their sturdy construction ensures that they will not collapse or collapse under heavy loads, providing maximum safety for personnel and equipment.

Top 4: Easy Maintenance

Steel cord conveyor belts are relatively easy to maintain compared to other types of conveyor belts. Their steel wire ropes can be easily replaced when necessary, making repairs and replacements quick and cost-effective. Additionally, the durability of these belts means that regular maintenance is required less frequently, saving time and resources.

TOP 5: Versatility

Steel cord conveyor belts are suitable for a wide variety of applications, including those that require transportation of materials over long distances, high angles, and variable speeds. Their ability to handle these different conditions makes them a versatile choice for various industrial sectors.

All YOU NEED KNOW About Steel cord conveyor belt

Steel cord conveyor belts are a crucial component in a variety of industrial applications. While their construction may seem simple, there are several factors to consider when selecting the best type of steel wire rope conveyor belt for your specific use case.

First and foremost, the material composition of the belt is crucial. Steel cord conveyor belts are typically made from high-quality wires that are twisted together to create a strong, durable, and reliable conveying surface. The quality of the wire and the degree to which it is twisted can have a significant impact on the overall performance of the belt.

Another important consideration is the temperature range in which the belt will be used. Steel wire rope conveyor belts are capable of withstanding high temperatures, making them suitable for applications in which heat is a factor. However, it’s important to consider that high temperatures can cause the wire rope to expand, which could lead to increased wear and faster replacement intervals.

Moreover, steel wire rope conveyor belts are typically used in high-wear applications such as mining, construction, and manufacturing. Their ability to withstand high levels of wear makes them a cost-effective solution in these industries where equipment replacement is frequent.

However, it’s important to note that steel wire rope conveyor belts do have their limitations. They are prone to rust and corrosion, particularly when exposed to moisture and saltwater. Therefore, regular inspection and maintenance are essential to ensure their longevity in such environments.

A Brief Self-Nomination, Why Choose us?

- Over 20 years of rubber conveyor belt manufacturing experience

- All rubber conveyor belt Meet and exceed ISO:9001 standards

- Complying criteria as DIN-22102 , AS-132, RMA,SANS-1173,BS-490

standards. - Flame resistant conveyor belt tested and certified with SGS

- One-Year Quality Guarantee, reply in 2 hours.

The FAQs About Steel Cord conveyor belt

Please note that the final cost depends on the customized service you require, the specifications of the raw materials used, the relevant national laws, and the distance of transportation. Take the example of booking a tall container of products:

1) CAN I GET ONE SAMPLE TO TEST??

Yes, No problem free samples, just need you bear the shipping cost.

The sample cost can be refundable after order confirmation.

2) WHAT IS THE DELIVERY TIME AFTER PAYMENT?

1. 3-5 days for sample

2. 15-20 days for mass production. If urgent,we have green channel, can do within 10 days

3) CAN I CUSTOM MY LOGO AND APPOINT THE COLOR ON THE PRODUCT?

Yes,just offer me your logo design with format so that our designer will make adisplay for your reference.

4) HOW ABOUT PACKAGE?

1. Inner is packed on round rubber core with 30cm diameter and 12cmx12cmsquare hole

2. Outer is packed with one ply water-proof Pp fabric

5) CAN YOU SUPPORT CUSTOMIZED

Yes, we can support customized conveyor belt width, thickness, length Vivamus euismod mauris.

6) WAHT'S THE MOQ

Support low MOQ, like 100 meter per roll